A s project size grows in complexity, so does the need for advanced tools for work-face planning. At its "Year in Infrastructure" conference in London, Bentley Systems Inc. in late October announced that its ProjectWise Construction Work Package Server (WPS), a system for managing the life cycle of work packages, is now being validated by industry firms and is scheduled for commercial release in early 2014.

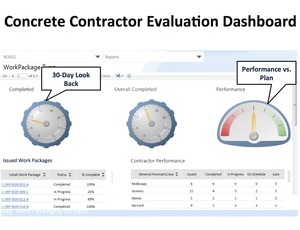

This server "manages information relationships, which enables you to manage change," says Harry Vitelli, Bentley vice president for construction and field applications. The tool helps "bring together a work package at the right time, for the right crew, with all the constraints cleared, and enables a project control team to get it out to the crew. The tool also gives a very rich set of reports and dashboards to track the work." Engineering, procurement, project controls and budget all work together on a common business process, he adds.

Bentley's ConstructSim V8i, used by planners for graphically defining construction work areas, creating work packages and performing 4D simulations for look-ahead planning, will be a client to the new server, which will handle document management workflow and reporting. The server was developed in response to the work of a Construction Industry Institute research team that has been investigating advanced work packaging and work-face planning for the past four years. Robin Mikaelsson, a Bentley senior application engineer, was on the team.

William J. O'Brien, a University of Texas professor and the academic lead of CII's Research Team 272, said using advanced work packaging principles on projects in the field, the team documented a 25% productivity improvement, a 10% decrease in total installed cost, greater schedule and cost certainty, improved safety and quality, and improved contractor profitability.

What makes this planning "advanced," O'Brien says, is the link to engineering. It assures that "the engineering work packages are aligned with the construction sequence on the field side," he adds. Glen Warren, from the Construction Owners Association of Alberta and a member of the CII team, explains with an example: Schedulers previously concentrated on the date equipment needed to be delivered to the site, but they may not have focused on the date when engineering needed data about the equipment's wiring requirements.

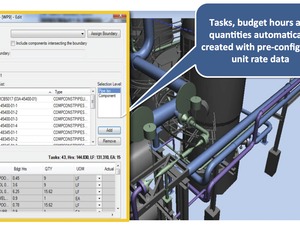

Vitelli relates these timely deliveries to the new tool, saying, "You choose a particular constructible model and draw a bounding box around a construction work area. Then, you are able to create a recipe for the work package, including the tasks, materials, schedule and safety parameters. ConstructSim understands the recipe and the geometric properties. It gives you tasks and quantities and all the documents. Is the work package ready to be issued? A constraint analysis tool looks ahead, clears the safety check list, checks that drawings are complete and materials are on-site before confirming the package is ready to go to the field."

Terry L. Erhart, global construction processes and technology director for Hatch USA, said staffers worked with Bentley to validate the tool using data from a completed project. He anticipates up to 90% time reduction for the staff associated with preparing work packages. But the more significant advantage "is in the increased productivity in the field by our contractors due to the entire work package planning process. This in-cludes the use of the Bentley tools: ConstructSim, tested and ready for deployment, and the WPS, which we are currently testing and plan to roll out on a pilot project in the first quarter of 2014," Erhart said. "At Hatch, I'd like to use this on all types of projects. Whether the job is $20 million or $2 billion, packaging the work is still an important aspect."

Post a comment to this article

Report Abusive Comment