Virtual design and construction is gaining ground in the utilities markets because of its ability to speed large-scale planning and development of energy projects. Though current applications on projects have just begun to touch the full potential of the approach, experienced users are enthusiastic about the financial benefits of debugging a project by building it first on the computer.

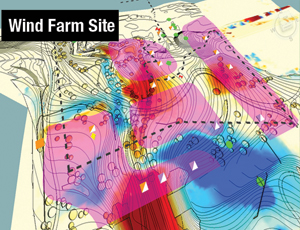

Minneapolis-based Mortenson Construction Corp. is saving money by using virtual design and construction (VDC) on energy projects, says Mark Ruffino, vice president of the firm’s renewable-energy group. Mortenson uses building information models (BIM) to overcome terrain constraints on wind-energy sites and to plan laydown and erection of turbines. “We can fine-tune what we disturb,” he says.

Mortenson models turbine siting to find pinch points and develop rigging protocols “so teams have an efficient plan,” says Ruffino. He notes that the nacels, or generating cores, are larger than school buses. “We have to figure where to set them up,” he says.

The cost savings can be significant. On a difficult wind-energy project in West Virginia completed last year, planners used VDC tools to layer environmental data, avoid artifacts from logging operations and steer around the most difficult terrain. “It was a huge benefit,” Ruffino says.

Charles Hixon, business development manager at A/E/C Bergmann Associates, Rochester, N.Y., thinks VDC will continue to evolve. A founding member of the Transportation Research Board’s visualization committee, he says current VDC integration has not reached its potential. He sees business opportunities for new approaches in project management and vendor support.

Traditional CAD software developers, which have saturated that market, are big drivers behind BIM, Hixon says. But it could be a win-win situation, for designers and vendors, if the BIM tool enables teams to produce better designs, he adds.

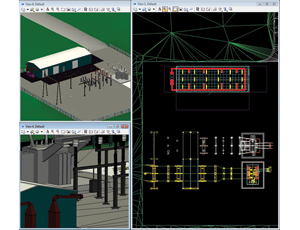

One new VDC tool for electric-utility substation planning is Bentley Substation V8i from Bentley Systems Inc., Exton, Pa. The firm anticipates a growing market for widespread system upgrades incorporating smart-grid technology, as well as system growth worldwide. Mike Lambert, V8i product manager, says the tool builds an intelligent information model for design, construction and operations that integrates with enterprise-wide engineering content-management systems. Users can work in 2D electrical schematics, 3D isometrics or navigable models and automatically generate bills-of-materials.

Hixon says current limits of VDC tools force project managers to consult different specialists for different pieces of the project to get the required information, rather than see all the data at once.

“It is not integrated very well….We need to allow project managers to see every part of that data simultaneously,” he says, adding, “3D design itself is effective, very powerful, but we want to link it to other data....Think Google Earth.”

Post a comment to this article

Report Abusive Comment