Facilities engineers often manage rotating equipment on a time-based schedule. Absent that, they may have to run systems to failure or until something breaks as part of their maintenance plan.

A new software tool is helping them get a better handle on life-cycle performance by diving into historical data about the machines.

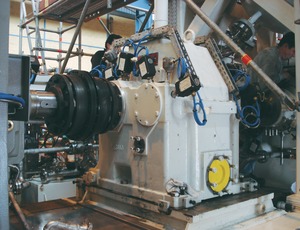

The software, called Capstone RBMI Rotating Equipment, is from Lloyd's Register Energy Americas, part of the 252-year-old company that also insures capital-intensive assets in energy and transportation. Drawing on Lloyd's experience in risk management and its extensive records, it is the first reliability-based mechanical integrity software for strategizing the maintenance of rotating equipment, the firm claims.

"Our company has successfully monitored fixed equipment, like vessels and pipes, with our Capstone software," says Jarret Reeves, product manager at Lloyd's Register. However, he says rotating equipment needs more complex assessment than fixed equipment because it has a greater variety of components, damage mechanisms, damage rates and usage-to-failure times. Also, it typically comes with less documentation.

The software uses equipment-specific risk models, adding variables such as environment, use and other factors, to make base mean-time-to-failure predictions, says Reeves. It also factors in the manufacturer and model "to predict how often a component will fail," he says.

The benefits of risk-based maintenance come from the component-level data and the analysis behind it. "With a time-based approach, you're checking non-critical components as much as critical components," says Reeves. "We want to help companies avoid failures altogether."

Post a comment to this article

Report Abusive Comment