After the March 2011 Fukushima Daiichi nuclear-plant accident, the U.S. Nuclear Regulatory Commission (NRC) issued an order for nuclear facilities to install reliable, extended-range instrumentation for spent-fuel-pool levels that meets new disaster standards. Last July, the first device was installed, says the device's designer.

Two companies recently announced the successful release of a measurement system that meets the new NRC standards, but Westinghouse Electric Co. LLC, Monroeville, Pa., installed the first device in a live plant: Watts Bar Nuclear Plant in Spring City, Tenn., operated by the Tennessee Valley Authority.

“We’ve been working on this application for two and a half years, and it meets all the standards,” says Stephanie Harsche, product manager for Westinghouse. The NRC order was made to address catastrophic events in which power is out and there is no access to the spent-fuel pools, says Harsche. The new measurement device has backup battery power for seven days, and it uses guided wave radar (GWR) technology to measure water levels.

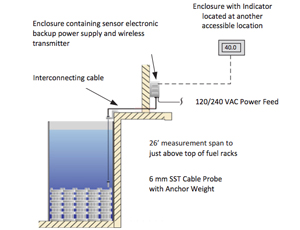

Harsche says the system has a stainless-steel cable probe suspended in the spent-fuel pool by a seismic Category 1 bracket. The cable probe almost touches the spent-fuel racks in the pool, but all its electronic components are housed in an adjacent room, protected from radiation and high temperatures that could come from a loss of pool water. These electronics are connected to the battery power supply. A transmitter sends the value of the pool and water level to a remote location, says Harsche.

The new NRC regulation is part of lessons learned after the Fukushima event, says Gary Brassart, Westinghouse vice president of automation engineering and projects. “It’s less distracting for the operators to have direct knowledge of the water level in a pool,” he notes. Westinghouse currently has contracts to install 90 of these systems in other nuclear facilities, he adds.

“The Fukushima utility didn’t know how much water was in the spent pool,” says Brandt Mohr, chief technology officer at MOHR Test and Measurement LLC, Richaland, Wa., who says his company developed a comparable GWR device to Westinghouse’s.

“No electronics will reliably survive an event like this,” observes Mohr, who says the NRC requires the device to withstand a boiling, saturated steam environment for more than days. He says his system can measure, at a thousand ft away, a water level within an inch with a standard coaxial cable.

Post a comment to this article

Report Abusive Comment