Virtual design tools are a real growth trend for illustrating delay claims in construction, say contractors and practitioners—with good reason.

For one, adding a project's CPM schedules to the finished project's 3D building information model to create a 4D BIM as-built model is a much easier way to tell a complex construction story to a lay audience—and build a delay claim. That's in addition to the obvious perk of improving scheduling and optimizing site layouts, among other benefits.

"I call it a gold rush right now for [vendors] who want to get into that middle space between the 3D software and the scheduling software" to generate 4D models, says Ben Nolan, a managing partner with Berkeley Research Group, a forensic schedule analysis and consulting firm. The Gulf Breeze, Fla., outfit specializes in creating 4D models in construction disputes.

When done right, these tools tell a powerful tale of what really happened on a project. But they take a lot of work to pull together.

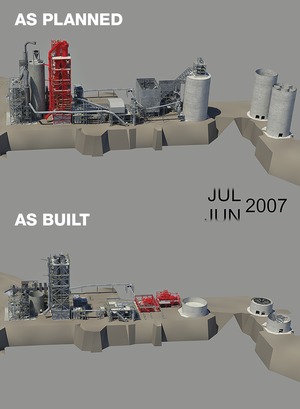

Consider the example in the lead image with this article taken from an animation of a cement plant in the Southeast U.S., which involved an estimated $40 million in claims. Nolan's team built the animation after a painstaking process of piecing together complex schedules on the project, whose scope was to add a new production line to the existing facility.

The top left portion of the image in the "as planned" section shows the upstream portion of the plant design, where aggregates would be crushed before they are sent to a heating tower, shown in red. As the longest path through the project, the 300-ft tower was considered the critical path. It had the earliest start and took the longest to finish.

"However, there was a high demand for steel and labor at the time this project kicked off, and all of those components could not necessarily come together at the right time," says Nolan. Labor shortages and steel and equipment availability issues mounted, which consumed the project's float as it fell behind schedule. In the lower, "as built" portion of the image, the critical path has shifted to the project's finish mill (the two red structures). By then, finger-pointing was under way.

"We built this [animation] with our 4D tools to explain the issues, which drew a common understanding of how they impacted things," Nolan adds. "It helped [the parties] reach a settlement out of court." The parties later told him that if 4D had been used sooner, it likely would have accelerated their negotiations.

But it's a tricky process. Kevin Coyne, a principal engineer with Coyne & Church of Alexandria, Va., says 4D BIM has its limits with delay analysis. "Some of the techniques that we use to visualize and analyze project delays within a 4D model are not yet fully automated in the off-the-shelf 4D modeling software that is currently available," he notes. "Consequently, many of these techniques must be performed manually or with customized software. In addition, the use of 4D models as demonstrative aids and trial graphics in dispute-resolution proceedings has been met with reluctance by some parties who are unfamiliar with the tool."

Shawn Pressley, a construction scheduling and technology executive with IT consultancy Envision, would agree that plenty of contractors are skeptical, largely because of the costs involved and whether the complexity of the project demands the investment.

"Will it work? Yes, 100%. But you have to get a [Revit or BIM tool] license. You will also need to have a scheduler who understands what the project is" and who can assure all the logic ties for every activity are well documented. Those files can become costly to manage, he adds. "For instance, if you're working on a steel model and tracking attributes to every piece of steel, in every steel bolt or its curves, that takes a lot of processing power to show that movie rendering."

Though they still are an investment, 4D BIM tool prices have come way down compared with 10 or 15 years ago, adds Andrew Ness, a construction attorney and partner with the firm Jones Day. Ness recalls spending between $150,000 to $200,000 in the mid-1990s to produce a forensic animation on a complicated case involving an industrial plant with some $30 million in dispute. But the client knew there was no way a jury would understand what happened without it.

"Now you can do it for $40,000 or $50,000, so you have to keep it in proportion to how much is in dispute," he says. "It's a compelling way to tell a story—if you've got a good story to tell. What people are finding is that the 4D BIM models are being produced as part of the [project] layouts. It's especially useful on a big project that's spread out where you can see how the critical path jumped around and shifted."

So the decision to invest in 4D BIM is always in proportion to how much is in dispute or at risk. "If you're trying to tell the story of what happened on D-Day in France in 1944, you could use lists of ships, maps and armies to explain it," Ness says. "Or you could show the first half hour of the movie 'Saving Private Ryan.'"

Adds Coyne: "Widespread implementation doesn't happen overnight. I'm confident that it's only a matter of time before 4D modeling gains acceptance as a mainstream tool used for delay claims."

Post a comment to this article

Report Abusive Comment