Researchers are developing a nano-material they hope will pinpoint exact locations of structural strain; the nanomaterial will self-diagnose dynamically and measure the strain.

The material is fluorescent silicon nanoparticles (Si-NP), and the research seeks to validate relationships between the Si-NP fluorescence peak and the macro-level state of strain.

The success of the research revolves around a phenomenon known as the Stokes shift, which refers to the longer wavelength of electromagnetic energy emitted as a result of losing some absorbed energy, says Charles Marsh, project leader at the U.S. Army Engineer Research and Development Center’s Construction Engineering Research Laboratory (CERL) in Champaign, Ill.

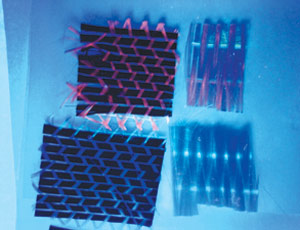

In other words, the small Si-NP fibers embedded in the material glow under ultraviolet light. The wavelength of light they emit is visible under UV and alters the Stokes shift according to the amount of strain it undergoes. The Si-NP have elastic properties and dynamically adjust to physical stress.

Think of an I-beam under load. At mid-span, the force pushing down places the bottom flange under tension. The tension level can be monitored by material pasted tightly on the beam and impregnated with the silicone quantum dots. Since the Si-NP undergo the Stokes shift, they will emit different wavelengths of light, pinpointing the load’s stress points.

“We have successfully experimented with this material,” says Marsh. When the current contract expires in September 2012, he says, CERL may conduct additional research.

Post a comment to this article

Report Abusive Comment