New product announcements: 12/09/2009

| Finishing Concrete Bridge Decks: All-Hydraulic Rig The Model 4836B Bridge Deck Finisher has all-hydraulic controls for both the mainframe and the dual-roller finishing carriage, allowing for much simpler operation than previous models. The broad 36-in. mainframe and 5-in. finishing carriage lift are powered by 25-hp engines. A hydraulically controlled roller tamper allows for fine adjustments to surface finishing, and a single-piece drag pan prevents seams from forming. Allen Engineering; 870-236-7751; www.allenpavers.com |

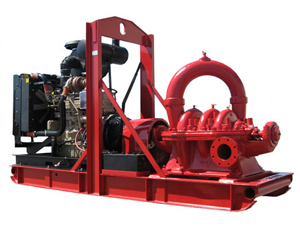

| Three-Stage Water Pump: Now With Tier 3 Engine The Three-Stage Jet Pumps from Griffin are now available with Tier 3 engines for better performance and reduced emissions. The water pumps are capable of delivering flow over 1,400 gpm and head conditions up to 900 ft. The pumps are intended for use in pipe and cassion jetting and field installation of well castings, as well as applications in environmental and pipeline work that require high flow and high pressure. Hand primers come standard, with automatic primers available as an option. Griffin Pump & Equipment; 866-770-8100; www.griffinpump.com |

| Heat-resistant Fall-Protection Harness: Welding on High The Thermatek Kit is a full-body harness intended for use in high-heat or welding applications. The harness’ webbing is made of a Kevlar/Nomex blend that is resistant to chemicals, weld splatter and other high-heat exposure. The Kevlar stitching on the harness is in contrasting colors for easier safety inspection. The shock absorber incorporates a Tuffweld protective cover to prevent high-heat damage and increase the life of the lanyard. It also features a Kevlar backup strap for extra protection. MSA; 877-672-2222; www.msanorthamerica.com |

| Floor Polishing: Discs Fit Standard Surface Grinders The Pro Polish floor-polishing discs are designed specifically to operate at the speeds of regular surface grinders. The 10-in. diamond polishing pads can be used on marble, concrete and any other polishable surface. The pads range from 50 to 3,000 grit and are color-coded for easy selection. According to the manufacturer, the pads can polish up to 15,000 sq ft of concrete over the course of their service life. General Equipment Co.; 800-53300524; www.generalequip.com |

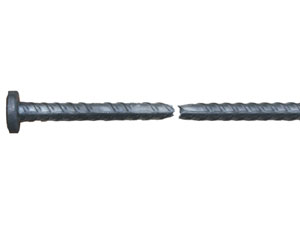

| Reinforced-Concrete Headed Bar: Pressed Rebar The HRC 555 headed bars for reinforced concrete are designed to meet new standards set by ACI and ICC-ES, including a reduced head-bearing area. Unlike the HRC 100 and 200, which are friction-welded, the HRC 555 is forged from a single piece of rebar using mobile equipment. The HRC 555 equipment is available from HRC under short-term rental or long-term leasing options. Headed Reinforcement Corp.; 800-472-6775; www.hrc-usa.com |

Post a comment to this article

Report Abusive Comment