The high cost of underground work needed to install geothermal tubing is inspiring some installers to develop cheaper alternatives. One unusual machine, called a SpiderPlow, is gaining traction in Canada.

Jim Bererton, who heads consulting engineer Stantec’s sustainability practice in Calgary, Alberta, brought in the SpiderPlow for a Walmart store under construction in Burlington, Ontario. With 15 km of tubing buried under the front parking lot, the 135,000-sq-ft building is the country’s first big-box store to go geothermal, according to Walmart. It opened in January and is 60% more energy-efficient than typical stores.

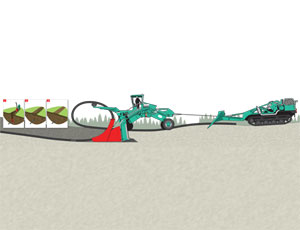

Operated by Calgary-based SpiderPlow Services Inc., the machine placed two runs of horizontal tubing, one at 5 ft deep and at 7 ft—simultaneously—without destroying the subgrade that eventually supported the parking pavement.

The plow actually is a “spread” of two machines: A tracked rig anchors itself into the ground and reels in a 44-mm-dia cable that pulls the plow, the legs of which articulate over obstacles. As the plow digs and places, the thin trench caves in, securing the pipe.

“We can lay up to 6 km of pipe a day at 8.5 ft,” says Allan Fowler, president and CEO. “There is no other machine that can do that.” Bererton calls it a “huge time-saving measure” for a job that would have taken months with a typical trencher or excavator. “We did it in six days,” he says.

Developed in Germany 50 years ago and built by a small company near Munich, the rig works mostly on oil, gas and water lines, says Fowler. His firm owns five spreads, worth about $2 million each, and rents them out, fully staffed, on a per-meter basis. One rig, he notes, does the work of 25 excavators at a fraction of the cost.

Post a comment to this article

Report Abusive Comment