Bernie Maez is frustrated by the lack of alternatives to higher-costing trucks and equipment. “We are always looking for ways to save fuel, but nothing is really working yet,” he says.

So instead of buying new, alternative vehicles, the director of fleet maintenance for Denver International Airport hopes to save money and pollute less by retrofitting older ones. Next month, he plans to begin testing a 2002 Chevy Silverado 2500 pickup truck fitted with a hydraulic hybrid kit that weighs just 250 lb.

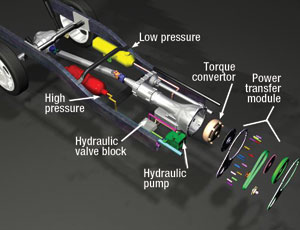

Developed by Loveland, Colo.-based Lightning Hybrids Inc., the kit fits on any vehicle and offers up to a 40% fuel-economy improvement. The firm was a sensation at the Denver Auto Show earlier this year, with a lightweight sports sedan powered by a 90-hp Volkswagen engine and a 150-hp hydraulic pump. Designed to run on biodiesel, the sedan can speed off the line to 60 mph in 5.9 seconds, and average fuel economy is 100 mpg, says the firm.

The company is expanding into more-practical fleet-vehicle kits that cost $13,000 for a pickup and $25,000 for a Class 8 truck, plus installation costs, says Richard LeFrancois, president of EMI-Global, a consultant who brokered a no-cost test drive for DIA. “If I don’t like the system, they’ll pull it off,” says Maez. The system also is expected to cut DIA’s maintenance costs. “Work equates to fuel used,” LeFrancois says. “So you are extending the life of the engine.”

Patented by the U.S. Environmental Protection Agency—and thus in the public domain—hydraulic hybrids may become a competitive alternative to traditional diesels. Next year, diesel trucks will cost up to $10,000 more due to scrubbers required to cut nitrogen-oxide emissions. Off-road diesels will begin phasing in similar controls now through 2014.

Urea injection, a common NOx solution, will require drivers to periodically fill up a tank of exhaust fluid or the truck eventually will shut down. Even though some experts think urea is a short-term answer, they are pessimistic on long-term prices. “We think urea’s got a short life,” says Philip Gott, an automotive-technology analyst at Lexington, Mass.-based IHS Global Insight. “There will be non-additive technologies that will prevail. It’s not going to change the cost much—what it will do is make it more convenient.”

Though fueling stations are limited, natural gas also is getting a second look. Compressed and liquid NG can run in existing engines with few modifications—few scrubbers, too—and come with tax credits of up to $32,000. Comparing NG to a 2010 diesel, “the economics get very interesting,” says Andy Douglas, a sales manager for Kirkland, Wash.-based Kenworth Truck Co. In the case of a spark-ignited, 9-liter engine that Cummins offers, “you have come very, very close to offsetting all of the cost,” he adds.

Another alternative is diesel-electric drive, like Caterpillar’s D7E dozer. Environmentalists like the D7E’s ability to curb pollution with its narrow-rpm engine. Scientists, too, increasingly are linking diesel fumes to cancer, though they have not yet evaluated today’s clean diesels. Hybrids may provide a necessary bridge to even cleaner fuels.

DIA plans this fall to use its overhauled pickup—powered by CNG—to make repairs to concrete runways. Other alternatives may appear on the tarmac, but so far, Maez says, there is no clear winner: “It’s hard to put all your eggs in one basket, because all the eggs are cracked.”

Post a comment to this article

Report Abusive Comment