Well before embedded instrumentation delivered data from a February 2009 lateral load test of a bent and pier of the I-10 Twin Span Bridge in New Orleans—and long before the sensors begin a life of service as long-term structural-health monitoring aids this October—devices cast into the bridge's structure were presenting a wealth of data to the industry.

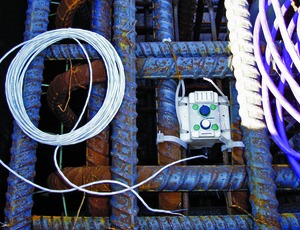

“The instruments that are in the pile foundations had to be placed in the rebar cages for the piles in the casting yard,” says W. Allen Marr, president and CEO of Geocomp Corp., Acton, Mass. The concrete was poured around corrosion monitors, other sensors and polyvinyl-chloride conduits, which provide channels for adding any new instrumentation and cabling.

Geocomp began monitoring stresses in the piles through readings of embedded strain gauges, heat sensors and in-place inclinometers, from the day of their casting to their installation. The firm monitored the concrete pour, the cure, the pre-stressing, transport to storage, and the strains endured as the piles were loaded onto barges for shipment down the Mississippi River, from Memphis to New Orleans. It also monitored off-loading, positioning for installation and every blow as the piles were driven into Lake Pontchartrain's bed to become part of the new bridge foundation. The data reveals whether the piles were properly created and handled, says Marr.

Instrumentation has been embedded in pilings before, Marr adds, but not on the scale done for the Twin Span Bridge's structural-health monitoring tests. Twelve of the foundation piles on pier M-19 of the bridge's main navigation span have embedded strain gauges at 16 ft and 21 ft below the pile tops. Six in-place inclinometers were installed on eight piles at the 5-, 15-, 25-, 35-, 45- and 65-foot marks from the bottom of the pile cap. When complete, the bridge will sport 340 sensors, including weigh-in-motion sensors, corrosion meters, strain gauges, tilt meters, inclinometers, accelerometers and water-pressure cells.

“Those readings of each of those sensors are valuable to quality-control people and design engineers,” Marr says.

Post a comment to this article

Report Abusive Comment