Design and engineering of a major new pipeline to deliver natural gas from Alaska’s North Slope to Alaskans and the export market is set to begin following the signing of a commercial agreement between the state, three North Slope oil and gas producers and a pipeline company. With the July 2nd agreement, the project now enters the pre-front end engineering and design (pre-FEED) phase, a milestone no previous Alaska gasline project has achieved, according to Alaska Gov. Sean Parnell (R).

The estimated cost of the Alaska LNG project (AKLNG) is staggering—$45 billion to more than $65 billion. The concept, which the Office of the Federal Coordinator for Alaska Natural Gas Transportation Projects calls one of the world’s largest natural-gas development projects, is ambitious. It embraces construction of a gas treatment plant that will gather, and remove impurities from, natural gas from two North Slope producing fields, construction of a pipeline approximately 800 miles long to carry the treated gas to a terminal on south-central Alaska’s Cook Inlet and a plant to be built there, probably at Nikiski, 60 miles south of Anchorage, to liquefy the gas for export to Asian markets. Up to eight compressor stations will maintain pressure and temperature along the pipeline route. At least five off-take points will allow Alaska municipalities along the way to tap the pipeline for their own markets.

The modularized gas treatment plant, sea-lifted to a North Slope location near Prudhoe Bay, will operate with four amine trains with compression, dehydration and chilling. A 58-mile, 30-in. pipeline will be laid to deliver gas from the Thomson Point-producing field to the treatment plant. The 800-mile, 42-in. pipeline will be laid primarily underground. The 30,000-horsepower compressor stations will supply more than 2,000 psi pressure to transport 3 billion to 3.5 billion cu ft of gas per day.

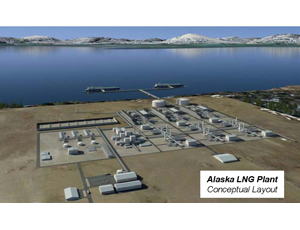

At the terminal, a liquefied natural gas plant with three trains will be built to receive and liquefy 2.2 billion to 2.5 billion cu ft of gas per day. Each train will have a capacity of 5.8 million tons per year, giving the plant a total capacity greater than 17 million tpy. Construction of LNG storage tanks and a conventional jetty with two berths to serve 15-20 LNG carriers per month will complete the plant. At peak construction, the entire project will generate 9,000-15,000 jobs, according to a 2012 estimate.

The July 2 agreement was signed by the Alaska Gasline Development Corp. (AGDC), BP Plc, ExxonMobil Corp., ConocoPhillips Co. and TransCanada Corp. The five entities plus Alaska’s commissioners of natural resources and revenue signed a heads-of-agreement in January that identified the main issues relevant to the JV and laid out the principles for its operation. That agreement provided the basis for legislation in April allowing the state to take a 25% stake in the project.

Monetizing the North Slope’s stranded natural gas has been an Alaskan dream since 1968, when an estimated 26 trillion cu ft of gas was found along with the discovery of the North Slope oil reserves. Piping the gas to market was uneconomic for a variety of reasons until about 2000, when declining North Slope oil production, rising gas prices, long-term market projections of growing U.S. demand and other considerations combined to make the business case for a gas pipeline. But plans to deliver the gas to the contiguous 48 states via overland pipeline through Alberta, Canada, were undercut by the late-2000s glut of shale gas, which drove the fuel’s price to record lows.

Future States

There is no certainty that AKLNG will survive changing market conditions or the gauntlet of decision points to come. The immediate threat is an Aug. 19 state ballot initiative to repeal a 2013 law on tax reform that creates an investment climate favorable to the massive investments required for projects like AKLNG. The pre-FEED that begins in July is expected to continue for 18-24 months. FEED, starting in 2016, will run about three years. A final investment decision would be made in 2019. If it is favorable, construction would begin then and be completed in 2023 or 2024.

At each juncture, the project could be judged economically unfeasible and terminated. Many other agreements and decisions required before the final investment decision could also determine the project’s fate.

AKLNG has overshadowed a far smaller gasline following much the same route but with a more limited purpose. The Alaska Stand Alone Gas Pipeline (ASAP) has been in the works since 2010, conceived as a 737-mile-long, 36-in.-dia pipeline with a single compressor station, originating at Prudhoe Bay. A “gas conditioning facility” would remove impurities and transport 500 million standard cu ft of lean gas per day, terminating near Point MacKenzie, 12 miles north of Anchorage. ASAP would have no LNG plant; total cost is estimated at $8 billion.

ASAP and AGDC were created together in 2010 when the state legislature mandated construction of an in-state gas pipeline and AGDC was formed to oversee the work. Parts of it have now progressed to FEED. Michael Baker International is doing pipeline engineering, a joint venture of FluorCorp. and WorleyParsons called Arctic Solutions is designing the gas conditioning facility and in September 2013, CH2M Hill was named program manager for ASAP. All three entities are working under master services contracts with task orders, says Frank Richards, AGDC vice president and program manager. Committed costs to date have been $24.9 million to MichaelBaker, $58.3 million to Arctic Solutions and $11 million to CH2M Hill, he says. The state is covering these costs with a $400-million subsidy, of which $176 million has been spent.

The AKLNG route has been refined from Prudhoe Bay to Livengood, 80 miles north of Fairbanks, and is being finalized from Livengood to Cook Inlet, Steve Butt, ExxonMobil’s project manager, told the Alaska Gasline Development Corp. board in May. ASAP, however, has secured easements for 95% of the route, says Joel Eacker, CH2M Hill’s senior vice president of major programs for oil, gas and chemicals. AKLNG will be able to use the geotechnical studies and easements ASAP has completed if it goes forward.

Planning two pipelines with overlapping missions strikes some observers as wasteful. But the state's long history of failures in completing even one gasline from the North Slope calls for a belt-and-suspenders approach. “We would always keep the ASAP project development as the backup plan,” Richards says. The completion of some ASAP work, like the right-of-way refinement, can save AKLNG costs, for example.

ASAP will have an open season, or solicitation for shippers, in the second quarter of 2015 and is scheduling a final investment decision for 2016. But AKLNG is scheduled to only begin FEED in 2016, with no FID before 2019. AGDC is overseeing both projects and will have some decisions to make then, says CH2M Hill’s Eacker. “They may choose to delay ASAP to align with AKLNG,” he says. “We are interfacing a lot with AKLNG, coordinating so we don’t waste money.”

ASAP’s open season will be an occasion for one of the first major choices, he adds. It will provide “some clarity around the (ASAP) project and how successful it will be.” It may require measures like conditional agreements with shippers to hold the door open for both projects a little while longer.

Post a comment to this article

Report Abusive Comment