Devices to harvest kinetic energy from the briny waste stream of seawater desalinization plants are to be used for the first time at an industrial scale in two plants now being built in Spain.

Pressure-exchange devices supplied by Energy Recovery Inc., San Leandro, Calif., are to be installed in reverse-osmosis plants being built by Spain’s Ministry of the Environment, Rural and Marine Affairs at the Mediterranean coastal cities of Moncofa and Oropesa. Together, the plants are expected to provide up to 21 million gallons of freshwater per day when completed in 2012.

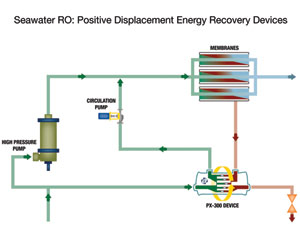

ERI’s PX Pressure Exchangers recapture water-pressure energy that is otherwise wasted in brine outflows on the reject side of reverse-osmosis membranes. With this system, pressurized water that normally would be discharged into the sea is first directed into a piston-less, energy-recovery device that uses the energy to help push raw seawater through the supply side of the membrane. The system transfers energy from the reject brine stream to the raw water stream with an estimated efficiency of 98%.

“It’s kind of like shooting pool,” says ERI chief technology officer Tim Dyer. He says the energy from the discharge water—or the cue ball in his analogy—is knocked into the raw water supply—the object ball—through four chambers in an almost frictionless, rotating ceramic casing, or Quadribaric rotor. Then, the energized raw water is directed toward the membrane through a circulation pump while the de-energized waste-stream water is drained away.

By performing the service of an auxiliary boosting pump, the exchanger lets the system run with smaller, high-pressure pumps on the supply side, thereby using as much as 60% less energy. Combined, the two Spanish plants could reduce power consumption by more than 2,000 kW annually, as compared with traditional systems, says Dyer.

The consortium of OHL Medio Ambiente INIMA, FACSA, RENOS and ISOLUX CORSAN is building the Moncofa plant. Reunidas S.A., Torresc�mara y Compa��a de Obras S.A., Assignia Infraestructuras S.A. and Ionics S.A.U. is combining forces on the Oropesa plant. Smaller versions of the device have been used in Los Cabos, Mexico, and in Algeria.

Post a comment to this article

Report Abusive Comment