A record-breaking 11-mile slurry wall in itself is unusual, but the relationship between contractor, engineer and owner is what makes the construction of the wall—at the Tennessee Valley Authority's Kingston fossil plant—even more unusual, says Brian Jasperse, president and CEO of Geo-Con, Pittsburgh.

“It's been a very interesting process,” Jasperse says. “It's a really good example of the engineer, contractor and owner trying to tweak the design. It's highly unusual, and as a result we're putting together a good product.”

Knoxville, Tenn.-based TVA and its remediation contractor, Edmonton, Alberta-based Stantec Inc., hired Geo-Con to construct a slurry wall around the base of the 90-acre coal-ash pond that failed in 2008, spilling 5.4 million cu yd of ash into the nearby Emory River and other adjacent properties. The wall will hold some of the ash that is being recovered as well as ash that remained in the pond.

The request for proposal was issued when the wall was at 30% conceptual design, so when Geo-Con came aboard, the firm had a great deal of input, says Don Fuller, the Stantec principal engineer responsible for slurry-wall design.

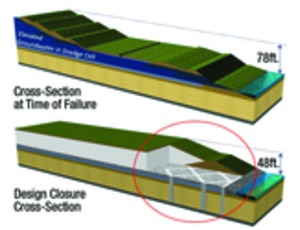

Stantec needs to ensure the wall can hold at least 12 million cu yd of coal ash in the event of an earthquake. The outer wall will have fortifying perpendicular walls and is designed to withstand a lateral load of 200,000 lb, Fuller says.

While Stantec didn't prescribe the construction method to bidders, Geo-Con determined that a slurry-wall trenching method—in which a cement-bentonite mixture acts as hydraulic shoring during excavation and then cures to become permanent backfill—would offer more consistent strength than soil mixing, which Geo-Con initially considered.

There are no prescribed methods to evaluate the physical characteristics of such a cement-bentonite wall, Fuller said. Geo-Con has helped Stantec refine the design, including determining when supporting walls can be tied into the perimeter wall. The contractor will use about 135,000 tons of slag cement and 16,000 tons of bentonite for the wall.

Jasperse says that the wall's cost started at about $25 million but now is expected to cost $45 million. But Barbara Martocci, a spokeswoman for TVA, says cost figures have not been finalized yet.

Post a comment to this article

Report Abusive Comment