The disaster set in motion on March 11 by a massive earthquake and tsunami struck Japan's Fukushima Daiichi nuclear powerplant in an unlikely place: its spent-fuel pools, where experts speculate that loss of water caused a nuclear reaction among the fuel rods, creating a hydrogen explosion that blew a hole through the pools' relatively flimsy exterior and released radiation into the air.

In the U.S., nuclear plant owners and regulators still say such an event is unlikely, not because exterior containment systems are more robust—they aren't—but because of redundant systems that would keep the water in the pools in the event of a similar incident. “Some simple measures that could have been taken early … would have avoided a lot of the problems [at Fukushima],” says Jeffrey S. Merrifield, senior vice president of the power division at The Shaw Group, Baton Rouge, La., and a former commissioner of the U.S. Nuclear Regulatory Commission. He is puzzled as to why the plant operators did not run firehoses into the containment pools, for instance.

Despite NRC reassurances, some utilities now are considering what activists and scientists have wanted for years: moving fuel from overstocked spent-fuel pools into dry-cask storage.

“They have to. I just don't see how they cannot take it seriously,” says Robert Alvarez, senior scholar for nuclear studies at the Institute for Policy Studies, Washington, D.C. He co-authored a 2003 paper that called on the nuclear industry to move more fuel to dry-cask storage. The report led Congress to order a second study in 2005 by the National Research Council, which also concluded that dry casks are inherently safer than wet pools.

Commission officials say they will examine spent-fuel storage in a 90-day review period. The Tennessee Valley Authority on April 14 said it might accelerate a move to dry-cask storage at three nukes. TVA's Browns Ferry reactors—as well as 28 others in the U.S.—are designed like the Fukushima Daiichi plant, with spent- fuel pools 70 to 80 ft above ground level. “I would expect that one of the things the NRC will consider is additional off-loading of fuel, which would clearly drive the need for additional cask utilization,” says Merrifield. Shaw's portfolio of dry-cask- storage work includes about half the 104 U.S. reactors at 64 sites.

From Temporary to Permanent

Spent-fuel pools initially were intended to temporarily house spent nuclear fuel until it was moved for reprocessing. But in 1977, the U.S. said it would not reprocess fuel. With no long-term storage plans, nuclear plants rearranged pools to accommodate larger amounts of spent fuel. NRC says 63,000 metric tons of spent fuel is now stored in U.S. pools. An additional 2,000 metric tons is produced each year during refueling at reactors.

The spent-fuel pools are robust. Each is about 40 ft deep, made of reinforced concrete 4 to 8 ft thick and fitted with a ¼-in. to ½-in. stainless-steel liner, says Kevin Crowley, director of the council's nuclear and radiation board as well as the staff director of its 2005 study.

Each pool's design is site-specific. Most are built on the same grade as the reactor to facilitate moving spent fuel.

The upended spent fuel rods are covered by 20 to 25 ft of water, which is the primary means of containing radiation. “You could remove the outlying building and there would be no consequence at all,” Crowley says. Unlike the exterior of the reactor core, which has to withstand a pressure buildup from within, the exterior of spent-fuel pools are simple metal- and-concrete structures, similar to Butler buildings, Alvarez says.

Following the Sept. 11, 2001, terrorist attacks, NRC ordered added safety measures at the pools. Fuel rods were reorganized to “checkerboard” the newer, hotter fuel with older less-combustible fuel. It also ordered all plants to add a secondary means of getting water into the pools, including sprayers on the edges of the pool or a secondary connection by which water could be pumped in from outside the pool. But Alvarez says, “[The changes] don't really go to the heart of the real problem: high-density pools in wet storage that were never envisioned to hold that much stuff.”

Despite the industry's insistence that no risk is posed by the exteriors of existing spent-fuel pools, all new reactor designs must analyze the impact of a hypothetical airplane crash into the spent-fuel pools. “It's safe to say that … 50 years of experience has improved [nuclear plant design],” Merrifield says. The spent-fuel pool of the Westinghouse AP 1000 reactor is covered by two 4-ft walls of reinforced concrete, while the designs of Paris-based Areva's new nuclear plants similarly protect their spent-fuel pools.

While the exterior building was breached at Fukushima Daiichi, it is unlikely NRC will require existing plants to harden the exterior of their spent-fuel pools. “It's not realistic,” Alvarez says. “I don't think it's economically feasible.”

What’s Next?

Instead, plants may accelerate the move to dry-cask storage. About 40 U.S. plants are moving to dry storage as spent pools reach capacity, says Everett Redmond, senior project manager at the Nuclear Energy Institute. All but one or two in the U.S. will follow suit, he predicts.

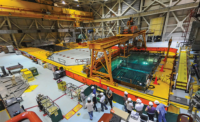

But Alvarez, the Union of Concerned Scientists and a growing number of politicians want spent fuel moved into dry- cask storage after five years of cooling in the pool. There are now 1,232 casks storing used fuel at a nuclear plant or offsite at another storage location, says NRC. The casks, aligned upright or lying horizontally, are placed on open-air reinforced concrete pads and use the airflow to passively cool the rods. Merrifield says the pads, which each hold 10 to 16 canisters, are built of reinforced concrete to last 60 years and withstand seismic events.

Utilities haven't rushed to embrace dry-cask storage because of cost. A November 2010 study by the Electric Power Research Institute, Palo Alto, Calif., estimates that moving spent fuel older than five years to dry-cask storage would cost $3.6 billion. Alvarez and others say the cost could be as high as $10 billion.

According to Alvarez, laws could be changed to allow utilities to tap into a $4-billion fund they have been contributing to for a long-term nuclear waste repository. The work could be done within 10 years. He concedes a plane or an anti-tank missile could breach a dry cask and release 5,000 to 6,000 curies of cesium but compares that event to a breach of a spent-fuel pool containing up to 30 million curies of cesium. “That's a huge difference in risk reduction and consequences reduction,” he says.

| 63,000 | metric tons of spent fuel is in U.S. pools |

| $3.5 billion | minimum estimated cost to move fuel into dry-cask storage |

| $83,000 | to dry store each metric ton of fuel |

| $25 million | cost to build average dry cask storage facility |

| 12 metric tons | of used fuel fit into an average-sized cask |

| $1.3 million | average cost to purchase, load and deploy one dry cask |

| $1 million | operating cost per year of dry-cask storage |

Post a comment to this article

Report Abusive Comment