The U.S. government will formally examine potential failure points of blowout preventers following a four-month-long forensic examination by a Norwegian firm into the failed device on BP's Macondo well in the Gulf of Mexico, Interior Secretary Ken Salazar said in an April 5 conference call.

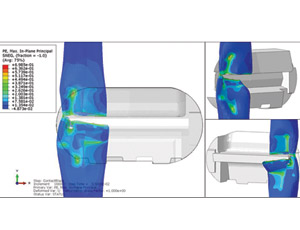

Following the well's April 2010 blowout, its blowout preventer (BOP) failed to stop the flow of oil and gas. The report, by Oslo-based Det Norske Veritas (DNV), concluded that blind shear rams, designed to cut the drilling pipe and seal off the well, failed to completely cut the pipe. The report said the pipe had become elastic and was off-center when the shear was activated. Issued last month, the study recommended further studies of BOP design changes and modifications. These studies might investigate the effects of oil and gas flow on BOP components and whether shear rams can properly cut a pipe that is not centered.

But the firm's conclusion and its recommendation that a study ascertain the conditions that led to the pipe's buckling came under scrutiny at federal hearings held on April 4-8 in Metairie, La.

DNV reached its conclusion by using computer modeling based on a physical examination of the BOP. But the pipe section that was apparently stuck in the blind shear ram was lost in the months it remained in deepwater. No physical evidence suggests the 5½-in.-dia steel pipe became elastic and buckled because of the force from below.

Ralph Linenberger, an independent BP consultant, testified on April 8 that the primary finding—that a piece of drill pipe buckled, became stuck in the blind shear ram and prevented the BOP from closing—was not evident to him. Upon looking at the pipe, he said there was no physical evidence the pipe buckled. He said he had never heard of a theory that a drill pipe could become elastic under pressure and buckle, as DNV said.

David McWhorter, engineering vice president of Cameron International Corp., Houston, which made the BOP, told the panel he would like to know the force level that could have buckled the drill pipe and pushed it off-center. He also wondered why DNV did not look at the very “legitimate possibilities” of temperature, flow and debris. Formal rule-making on BOPs could take up to a year.

Post a comment to this article

Report Abusive Comment