A three-story, $30-million hexagonal wind tunnel in Canada can recreate tornadoes and capture data to serve as a basis for developing twister-resistant structural design. It is the first facility of its kind in the world, says its co-designer.

The chamber, operating since early last year, has simulated the weakest types of storms, categorized by the Enhanced Fujita scale as EF-0, EF-1 and EF-2 events. "We are now preparing to test for EF-3 and EF-4 tornadoes," says Horia Hangan, director of the Wind Engineering, Energy and Environment Research Institute at the University of Western Ontario and co-designer of the WindEEE facility.

With WindEEE's hexagonal-in-plan shape, researchers can produce and digitally capture any type of 3D and time-dependent wind system. "Typical wind tunnels blow in one direction," says Hangan. WindEEE moves wind in every direction and can vary direction over time.

WindEEE has an 82-ft-dia inner chamber inside a 133-ft-dia chamber, separated by a 16-ft void for air recirculation. Five inner walls have eight 2.5-ft-dia embedded fans, and one has 60 embedded fans. Fan louvers guide airflow. To manipulate the storm, individual fan speeds can be increased, decreased or reversed within one second.

Six 6.5-ft-dia vertical fans, each facing the dome's center, hang from trusses above the inner chamber in the center of the dome. The floor of the wind chamber has blocks, called roughness elements, that can be raised or lowered—mimicking changes in topography.

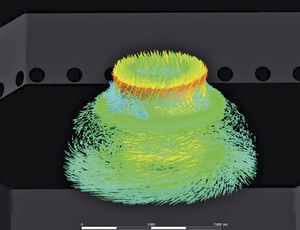

Tornadoes are simulated by injecting air into the chamber through the walls at a specific angle and ejecting air out the roof. The swirling wind, called a vortex, is invisible. Consequently, fog is introduced to allow researchers to visualize the flow, says Andrew Mathers, WindEEE's operations manager and co-designer of the test chamber.

The Canada Foundation for Innovation, an independent corporation created by the government to support research infrastructure, funded 40% of the cost of the lab, and the government Ontario Research Fund funded another 40%. The university put in 20%.

Hangan expects to have quantitative test data by year-end.

Post a comment to this article

Report Abusive Comment