Sparks are flying over a proposed addition to the 2010 edition of the steel sector’s code of standard practice. The addition would recognize the practice, in use for years, of the structural engineer of record designating connection design to a licensed professional engineer working for the steel fabricator.

“The fundamentals of this proposal are accepted,” says Charles J. Carter, vice president and chief structural engineer for the Chicago-based American Institute of Steel Construction Inc., at its North American Steel Construction Conference, held April 1-4 in Phoenix.

Carter, secretary of AISC’s 28-person committee on the Code of Standard Practice, put forth the proposal for Section 3.1.2 at the conference, attended by more than 3,200 steel fabricators, erectors, suppliers and structural engineers. The draft now includes a three options, not two: “1) The complete connection design shall be shown in the structural design drawings,” which means the structural engineer designs the connections; “2) The connection shall be designated to be selected or completed by an experienced steel detailer,” which means the structural engineer provides schematics and the detailer completes the details; and “3) The connection shall be designated to be designed by a licensed professional engineer working for the fabricator,” which means the structural engineer of record provides design criteria to a licensed engineer, who designs the connections. A method must be specified for each connection, but connection types can be grouped and a combination of options used.

Committee member D. Kirk Harman, president of the Harman Group, Philadelphia, is against the change, as were many engineers in attendance. Connections are the most common cause of claims and failures and the most difficult part of steel design, he said. “Can you really convey the connection requirements on drawings?” he asks. Harman does not think AISC should validate the process, which he says also raises liability issues, can add to schedule and can have an impact on cost because of the extra time for negotiation of connection design issues and for connection calculation reviews.

The new option does not condone or recommend practice but merely recognizes it, said E. Glenn Bishop, senior principal of LBYD Inc., Birmingham, representing the Council of American Structural Engineers on the committee. “We are not talking about what is the best way but what is being done,” he said. “This practice has been around for a long time.”

The code committee will vote on the revision for the third time by the end of May. If another ballot is necessary, it will happen later this year. Carter expects AISC’s board of directors to approve the change for publication during the first half of next year. It will then be released to the public and offered as a download at www.aisc.org, free of charge.

Structural engineers have to pay more attention to steel connections in another way, thanks to changes in the 2009 International Building Code that are meant to increase a building’s resistance to progressive collapse through stronger horizontal ties. Section 1614 of the code is applicable to buildings 75 ft or taller in certain occupancies, including schools, police and fire stations and jails, which are typically not taller than 75 ft, says Ronald O. Hamburger, senior principal in the San Francisco office of Simpson Gumpertz & Heger.

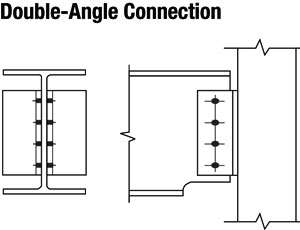

The good news is that, based on normal detailing used in ongoing AISC tests, many standard connections will meet the requirements. These include single-plate shear connections, bolted double-angle shear connections, end-plate shear connections, double-angle shear connections bolted to supports and welded to supported beam webs, and single-angle shear connections, said Kurt Gustafson, an AISC structural engineer.

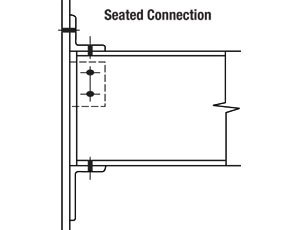

The bad news is that, depending on the magnitude of the axial tension force requirement, it is possible that double-angle connections welded to supports and seated connections may require modification or reinforcement, said Gustafson. Tests on these connections are planned.

Some engineers registered concern that, in some circumstances, requirements could cause a local failure in the building, pulling adjacent portions into collapse. “While this is possible, engineers in the U.K. believe that buildings there constructed with similar requirements did perform better when they were subjected to bomb attacks in the 1970s and 1980s, said Hamburger.

Post a comment to this article

Report Abusive Comment